Excitement About Brushless Dc Motor for sale - eBay

Make a Brushless DC Motor : 3 Steps - Instructables

The smart Trick of The Difference Between Brushed and Brushless Motors That Nobody is Talking About

When transforming electrical power into mechanical power, brushless motors are more efficient than brushed motors primarily due to the lack of brushes, which minimizes mechanical energy loss due to friction. The improved effectiveness is greatest in the no-load and low-load areas of the motor's performance curve. Environments and requirements in which manufacturers use brushless-type DC motors consist of maintenance-free operation, high speeds, and operation where triggering is hazardous (i.

China 5030 BLDC motor for Angle Grinder, 20V DC Brushless Motor on Global Sources,BLDC motor,Angle Grinder Motor,Brushless Motor

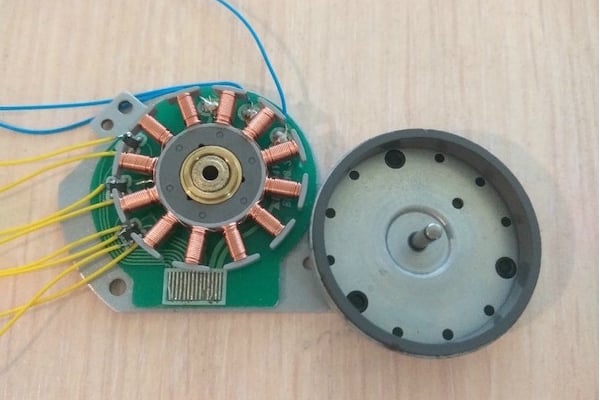

explosive environments) or could impact electronically delicate equipment. The building of a brushless motor looks like a stepper motor, however the motors have crucial distinctions due to distinctions in execution and operation. While stepper motors are often stopped with the rotor in a specified angular position, a brushless motor is usually intended to produce constant rotation.

Getting The DC Brushless Motors - Motors - Crouzet Motors To Work

Both a stepper motor and a well-designed brushless motor can hold limited torque at zero RPM. Controller executions [modify] Since the controller executes the conventional brushes' functionality it needs to understand the rotor's orientation relative to the stator coils. This is automated in a brushed motor due to the fixed geometry of the rotor shaft and brushes.

Others determine the back-EMF in the undriven coils to presume the rotor position, eliminating the requirement for different Hall result sensing units. These are for that reason often called sensorless controllers. Controllers that notice rotor position based on back-EMF have extra challenges in starting movement due to the fact that no back-EMF is produced when the rotor is stationary.

50-150 W DC Brushless Motors, Lt;100 V, Asif Electronic - ID: 20263659573

Some Known Incorrect Statements About Brush DC Motors - NMB Technologies

This can trigger the motor to run backwards quickly, including much more intricacy to the start-up sequence. Other sensorless controllers are capable of measuring winding saturation triggered by the position of the magnets to infer the rotor position. [] A normal controller contains 3 polarity-reversible outputs controlled by a reasoning circuit.

More advanced controllers employ a microcontroller to handle velocity, control motor speed and fine-tune performance. Click Here For Additional Info of brushless DC motors are the motor constants K T \ displaystyle K _ T (torque constant) and K e \ displaystyle K _ e (back-EMF consistent, likewise called speed continuous K V = 1 K e \ displaystyle K _ V = 1 \ over K _ e ).